OUR SERVICES

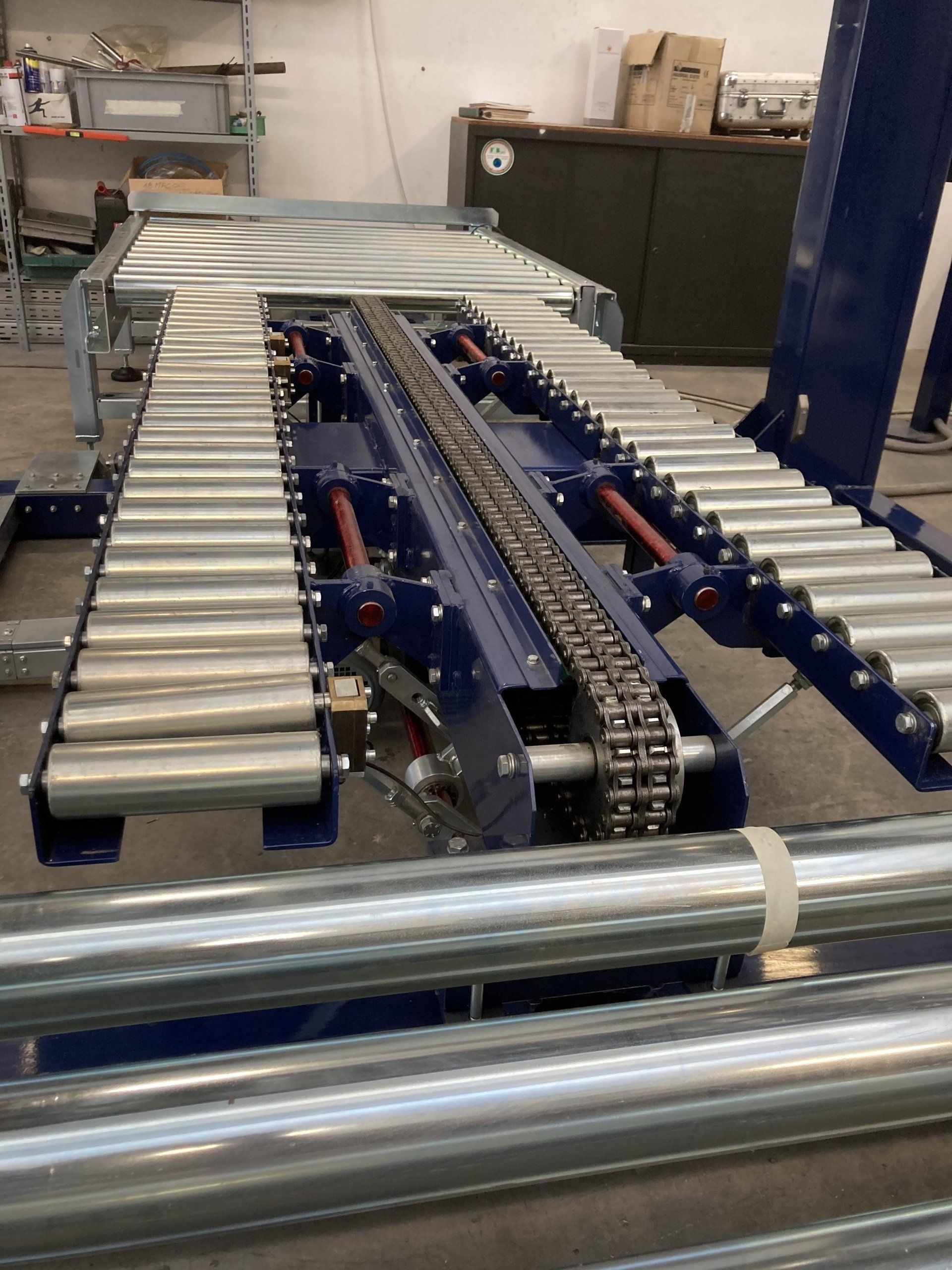

We offer a wide range of services, from the design to the construction of new plants to the revamping and adaptation of old and obsolete automation systems

ROBOTIC CELLS PALLETISING SYSTEMS

High Technology on Small Plants

We make palletising cells with the help of anthropomorphic industrial robots

Our islands guarantee maximum flexibility and efficiency to best adapt to the needs of the user, all solutions are designed and customised according to the needs of the customer

Always interconnected to systems outside the plant, they contribute to the process of digitalisation of the factory and allow accurate diagnosis using the remote assistance system

- Remote Assistance System

- Integrated management of production data and plant efficiency

- Automatic control of maintenance cycles

- Adopting high-efficiency motorisations resulting in energy saving

GRIPPER ;

All our handling tongs are designed in relation to the products to be treated always ensuring maximum accuracy in the handling of the items to be handled

- Multiple product sockets

- Socket and management of Interlayer

- Palette Taking and Managing

EDIBLE FILM CAPPING MACHINE

"SMARTHOODER®"

Countless working modes thanks to a practical and intuitive recipe menu that allows a wide customisation of the working parameters of the machine, automatic recognition of the size of the pallet for optimal product protection and consequent savings of Film

BEET SAMPLING AND ANALYSIS PLANTS

Landi Automation is honoured to present the range of production facilities for the Sampling and analysis of sugar beet. Through the acquisition of the brand and the know-how of the company that has been operating in the sugar industry for about 40 years. Experience makes it possible to offer the latest technology solutions integrated with Anton- Paar analysis tools that make up a package of solutions that began in the 1970s. Of course, in addition to standard solutions, we are specialists in creating customised solutions that meet customer needs

Revaming on Existing Plants

Revamping interventions on existing and/or Obsolete Automation Systems with PLC and HMI replacement, adaptation of existing security systems with adaptation to current regulatory standards

Integration of plants into business networks, including remote teleservice devices, resulting in optimisation of production processes and extension of the life cycle of machines